QUALITY

ASSURANCE

To adhere to highest standards of Quality Assurance, the material undergoes the below mentioned tests:

To ensure the highest standards of Quality Assurance, the material undergoes visual inspection, dimensional checks, mechanical and chemical testing, non-destructive evaluation, and performance testing. These tests collectively verify the material’s integrity, accuracy, and suitability for its intended application.

CHEMICAL COMPOSITION :

To confirm to IS 2831:2012 ,a meticulous Chemical analysis of every lot of billet is carried out in our chemical and Spectro lab. The billets thus tested are then moved for rolling.

MECHANICAL PROPERTIES :

The mechanical properties of bars are tested through –

Section Weight : ‘Weight per Meter’of the bars as per

IS:1786:2008 is checked by taking out sample after every

thirty minutes. Standards weight is always maintained

within BIS tolerance.

- Load Test : Yield Load, Ultimate Tensile Load and Elongation are tested using UTM of 100 Ton capacity.

- Bend Test : As per sizes specified in IS code, the bend test is carried out by bending the bars on mandrel.

- Re-bend Test: Bars are bent at an angle of 135°, kept in boiling water at 100°C for 30 minutes and then bent back at an angle of 157.5°.

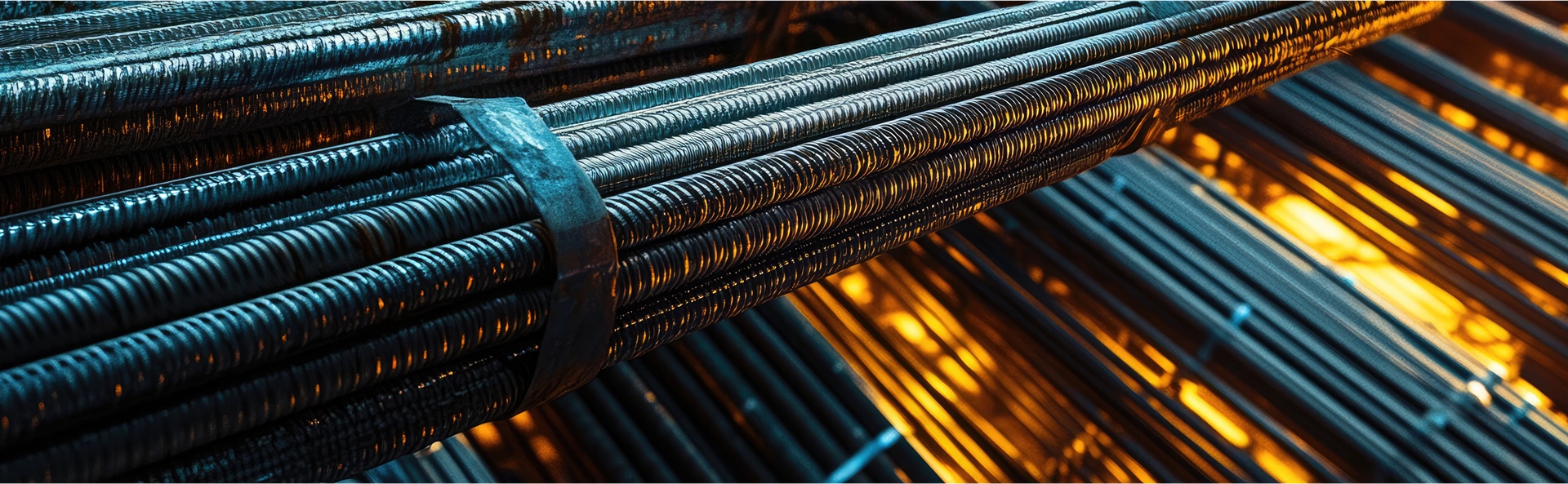

DEFORMATION AND

SURFACE CHARACTERISTICS :

The ribs are cut through automatic CNC Rib Cutting

Machine to get precise, uniform in shape ribs. Checks

are carried out at regular intervals.

Machine to get precise, uniform in shape ribs. Checks

are carried out at regular intervals.

AR Value (Area of Ribs) :

Calculation of the AR Value is the

Bond Test.

Calculation of the AR Value is the

Bond Test.

ETCHING TEST :

Bar ends are finished and polished like glass finishing and

dipped into Nitrole to visualise three distinct rings –

dipped into Nitrole to visualise three distinct rings –

- Outer Core of Tempered Martensite

- Middle Core of Mixed Bainite

- Inner Core of Ferrite Parlite. After all these the tests, Tagging, Packing, Storage and dispatch of material happens.

About Us

MODERN CHEMICAL

ANALYSIS EQUIPMENT

- German made Spectrometer for Quick and Accurate Analysis

- 7 Automatic Mould Level Control in Caster.

- Billet Micro Analysis for Internal Structure Control

DOCUMENTATION

All these processes are to adhere to BIS norms &

documented as per the ISO. Post the material test

tagging, packing & forwarding is been done.