About Us

About Us

Building a Resilient

Future, Forging a

Developed India By 2047.

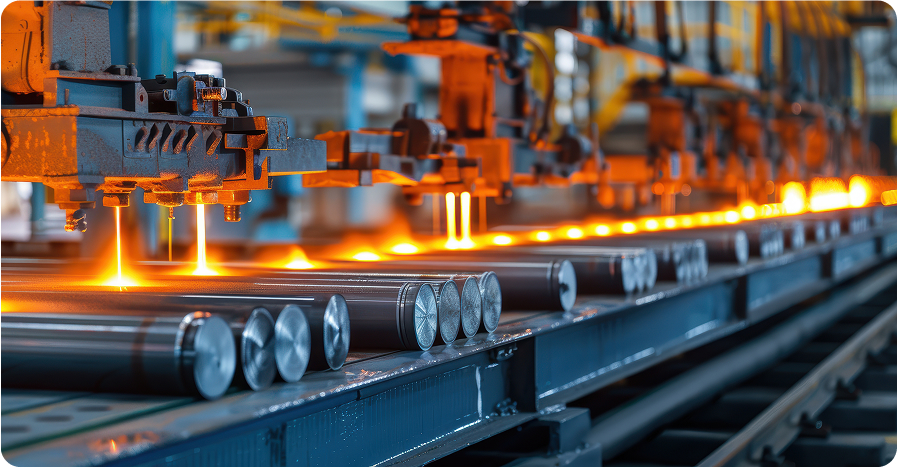

The rolling mill machinery is supplied by STEEFO INDUSTRIES, a reputed and pioneer name in Steel Rolling Mill Industry, having rich experience and global presence for four decades. Stallion TMT bars are a result of relentless drive, research by innovation and obsession for quality

Targeting a

$30

Trillion Economy

VISION

We aim to become a leading TMT bar manufacturer that supports the rapid growth of the Indian economy by delivering world-class quality steel products. We aim to empower infrastructure development, drive innovation, and promote sustainable practices, contributing to India’s progress as a global economic powerhouse

MISSION

To manufacture high-quality, durable and sustainable TMT bars that build stronger foundations for tomorrow, while upholding safety, innovation, and environmental responsibility in every aspect of our operations

India Aims To Become A Developed

Nation By 2047, The Centenary

Of Its Independence, Targeting

A $30 Trillion Economy.

1,00,000 sft

Manufacturing

Facility

2,00,000 MT

per annum

Production

50+

Professional

Engineers

Advanced

Manufacturing Process

Stallion TMT bars are manufactured using Continuous straight rolling process by fully automatic advanced technology, state-of-the-art machinery using Thermo Mechanical Treatment (TMT) to ensure high strength reinforcement bars.

Continuous straight rolling refers to a continuous flow of material through a series of rolling stands without any significant change in direction, while a “looping rolling process” involves the material being bent into a loop between rolling stands. As a result, Continuous straight rolling provides better dimensional accuracy and a more uniform finish, as the material undergoes steady deformation without interruptions.

Advantages Of Stallion Tmt Bars

Maximum Strength with Better Elongation

Stallion TMT bars have high tensile strength and better elongation value.

Superior Ductility

The advanced thermex quenching during the manufacturing process results in bars with tough outer surface but a soft core that translates into excellent bendability

Consistent Quality

Continuous rolling provides better dimensional accuracy and a more uniform finish, as the material undergoes steady deformation without interruptions.

Weldability

Low carbon content of Stallion TMT bars results in offering excellent weldability as compared to other TMT bars.

Better Bonding Strength

The consistent rib patterns and optimum rib depths of Stallion TMT bars enhances the grip and bonding with concrete.

Resistance to Fire Hazards

Stallion TMT bars can withstand high temperatures without losing their structural integrity

Earthquake Resistant

The high elongation and flexibility of Stallion TMT bars help them absorb and dissipate energy during seismic events.

Corrosion Resistance

The advanced manufacturing process of Stallion TMT bars provides superior anti-corrosive properties.

Cost Savings

Steel bars are bought in kilos and tons but their usage is in terms of metres. Stallion TMT bars have a higher metreage per unit weight which results in tremendous cost savings

MANAGEMENT

Mr Ramesh Bansal (Chairman)

Founded Woollen Textile industry in the year 1990 under the name of Prayas Woollens Pvt Ltd, a 100% EOU manufacturing and profitable unit having more than 400 employees. Has 40+ years of experience working in the manufacturing sector. A commerce graduate as well as an IIM Ahmedabad Alumni, having completed the SMEP Management course.

Mr Rahul Bansal (Managing Director)

Serving as the Managing Director at Prayas Woollens Pvt. Ltd, a textile manufacturing company, since 2010. Has 15+ years of experience working in the manufacturing sector. Has completed B.Tech (Industrial Engg.) from Ohio State University, USA, and MBA (Marketing) from Greenwich University, UK.

Mr Rohan Bansal (Managing Director)

Served as Investment Associate at Private Equity firm Kotak Investment Advisors Ltd focussed on Real Estate commercial and residential investments. Prior to that, served as Investment Banking Analyst at JP Morgan Chase & Co Has completed his B. Tech (IT) from DAIICT, Gandhinagar and MBA (Finance) from IIM Kozhikode. Post that has also cleared 2 levels of Chartered Finalist Course (CFA)